Table of Contents

What do we mean by springs?

Springs are technical components made of spring steel that can deform elastically. When subjected to stress, they give in and absorb force. When they relax, they release this energy and return to their original form. Steel springs, metal springs or technical springs come in a variety of shapes, materials and for different areas of application. Springs consist of, among other things Spring band steels, spring steel sheets or Spring steel wires . In addition, technical springs made of rubber and fiber-reinforced plastics, as well as gas pressure springs that use gases as an aid for suspension, can be made. Most types of feathers get their name from their appearance. One speaks of Shaped springs, ribbon springs, flat springs, leaf springs , from Spring clips or Spring clips , from Coil springs , Disc springs, wave springs, conical springs, barrel springs or ring springs. There are also types of springs that owe their names to their respective functions. Examples are compression springs, tension springs, torsion springs or torsion bar springs.

How do the springs differ from each other?

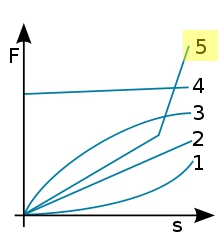

In addition to their shape and material, feathers are about the Spring constant or Spring characteristic Are defined. The spring constant describes the increase in force in relation to the spring deflection or the angle of rotation. The course of a spring constant is shown with the spring characteristic. It shows the relationship between spring force and deformation path. The elastic deformation occurs on the basis of the Hooke’s law . This describes the elastic deformation of solids when the deformation is proportional to the applied load. Most types of feathers have one linear spring characteristic (2) with an even force curve, one progressive characteristic (1), which increases in force with increasing deformation or a degressive curve (3) in which the force decreases during this process. In addition come combined spring characteristics (5), which change the force properties under certain stress states or distances, and flat spring characteristics with a small increase in force (4).

In addition to their shape and material, feathers are about the Spring constant or Spring characteristic Are defined. The spring constant describes the increase in force in relation to the spring deflection or the angle of rotation. The course of a spring constant is shown with the spring characteristic. It shows the relationship between spring force and deformation path. The elastic deformation occurs on the basis of the Hooke’s law . This describes the elastic deformation of solids when the deformation is proportional to the applied load. Most types of feathers have one linear spring characteristic (2) with an even force curve, one progressive characteristic (1), which increases in force with increasing deformation or a degressive curve (3) in which the force decreases during this process. In addition come combined spring characteristics (5), which change the force properties under certain stress states or distances, and flat spring characteristics with a small increase in force (4).

Areas of application

Give as elastic components technical springs under load and return to their original shape when relieved. Almost all applications in which technical springs are used are based on this function. Among other things, they are used to move machine parts and Switch contacts to close or open. When pre-tensioned, they can be used as Drive energy or as Restoring force in switches and torque wrenches. They also come as frictional connection for use – for example with door stops or friction clutches, for load distribution on a trampoline or with systems that can vibrate, where with the help of Spring systems kinetic energy is converted into potential energy and intercepted.

A selection of the most important types of steel springs:

Leaf springs

The term Leaf spring For a long time it was an umbrella term for suspension springs made of flat material such as Fully elliptical springs, semi-elliptical springs and parabolic springs . Today it is also understood as technical springs that are roughly differentiated between straight, curved, coiled or disc-shaped Flat spring .

The term Leaf spring For a long time it was an umbrella term for suspension springs made of flat material such as Fully elliptical springs, semi-elliptical springs and parabolic springs . Today it is also understood as technical springs that are roughly differentiated between straight, curved, coiled or disc-shaped Flat spring .

Straight flat springs

Straight flat springs can be done using a Stamping or stamping and bending machines out Spring band steel punch and shape. At small quantities or particularly filigree shapes, they can be lasered or etched. Flat springs are often used in contact systems of electrical switching devices – for example in relays. In this way you can Contact springs Install prestressed. Spring bronze is often used in the manufacture of contact springs CuSn6 and Copper beryllium CuBe2 used.

Straight flat springs can be done using a Stamping or stamping and bending machines out Spring band steel punch and shape. At small quantities or particularly filigree shapes, they can be lasered or etched. Flat springs are often used in contact systems of electrical switching devices – for example in relays. In this way you can Contact springs Install prestressed. Spring bronze is often used in the manufacture of contact springs CuSn6 and Copper beryllium CuBe2 used.

Curved flat springs and shaped springs

A general distinction is made between curved flat springs and shaped springs . The curved flat spring consists of straight lines and Circular arcs . It is usually made with a stamping and bending machine Spring band steel punched and shaped at the same time. Form springs, on the other hand, are mostly made in their basic form Spring steel sheet by Laser cutting cut out and followed by Forming by bending, embossing, edging and deep drawing produced. The variety of shapes and thus the range of applications are almost unlimited. The calculation of the force acting on the springs is complex and can be done using the Finite element method (FEM). For this purpose, feasible dimensions must be approximately determined manually in advance. Calculation models that are universal do not exist. Design guidelines are therefore important, in which in particular the Minimum bending radii must be observed.

Coiled flat springs: spiral springs and constant force springs

To the coiled flat springs counting Coil springs with and without a large space between the coils and scroll springs. The spiral springs are manufactured on radial bending machines. Among other things, they are very important in the automotive industry, where they are installed in seat belts, window regulators and locks. Roll springs are used, for example, in spring tension systems. Coiled flat springs are ideal as compensation springs for smaller angles of rotation. The stored force serves as a compensation or restoring torque. The Spring characteristic increases almost in a straight line. Both types of springs are wound in one plane according to the Archimedean spiral. A constant coil spacing ensures that the individual coils do not touch each other and also ensures that the springs function with little friction.

To the coiled flat springs counting Coil springs with and without a large space between the coils and scroll springs. The spiral springs are manufactured on radial bending machines. Among other things, they are very important in the automotive industry, where they are installed in seat belts, window regulators and locks. Roll springs are used, for example, in spring tension systems. Coiled flat springs are ideal as compensation springs for smaller angles of rotation. The stored force serves as a compensation or restoring torque. The Spring characteristic increases almost in a straight line. Both types of springs are wound in one plane according to the Archimedean spiral. A constant coil spacing ensures that the individual coils do not touch each other and also ensures that the springs function with little friction.

Disc-shaped flat springs

The disk-shaped flat springs include Disc springs and Spring washers . They are used as a single spring or in combination. Spring washers are devices that are suitable for certain screw connections. Disc springs are characterized by their high strength and are also particularly compact. As a result, they are often used in confined spaces with high forces. Disc springs can be used in Stamping process with subsequent cold forming and edge rounding. A special feature: force and spring travel can be changed by layering to form a disc spring column. Disc springs create a degressive spring characteristic .

The disk-shaped flat springs include Disc springs and Spring washers . They are used as a single spring or in combination. Spring washers are devices that are suitable for certain screw connections. Disc springs are characterized by their high strength and are also particularly compact. As a result, they are often used in confined spaces with high forces. Disc springs can be used in Stamping process with subsequent cold forming and edge rounding. A special feature: force and spring travel can be changed by layering to form a disc spring column. Disc springs create a degressive spring characteristic .

Spring clips: spring clips, spring clips and pipe clips

Spring clips – also Spring clips , Clamp springs and Pipe clamps called – are punched from spring band steel and formed or made from Spring steel sheet lasered and then shaped. The main characteristic is that frictional connection . They are used wherever components need to be adjusted, locked, locked or fixed in the right place. Among other things, they are used to hold paper in place, hold name tags or replace paper clips. In addition, they are suitable for hanging tools, hoses and the like.

Wellenfedern

Wave springs are also referred to as axial wave springs or wave springs. They are made of twisted flat wire and get their spring effect from the incorporated shaft. With a reduced installation height of up to 50 percent compared to conventional ones Compression springs , they are a space-saving alternative for static to medium dynamic use. Despite this reduced height, wave springs can generate the same force as compression springs, for example. The required spring constant can be determined and established through the number of turns, the waves and the wave sizes.

Wave springs are also referred to as axial wave springs or wave springs. They are made of twisted flat wire and get their spring effect from the incorporated shaft. With a reduced installation height of up to 50 percent compared to conventional ones Compression springs , they are a space-saving alternative for static to medium dynamic use. Despite this reduced height, wave springs can generate the same force as compression springs, for example. The required spring constant can be determined and established through the number of turns, the waves and the wave sizes.

Torsion springs

Torsion springs or torsion springs are coiled wire springs with tangential legs. These mechanical energy accumulators take on an angular and rotary movement on the legs Torque that they give off when they relax. Torsion springs are made from round, oval or square spring steel wire – normally cylindrical with a constant pitch and no spacing between the windings. Depending on the application, the Leg out, for example, straight tangentially, radially inside or outside, axially or axially parallel. Particularly important: you should only ever load torsion springs in the direction of the coil. Therefore, they are offered with identical left and right-hand winding.

Torsion springs or torsion springs are coiled wire springs with tangential legs. These mechanical energy accumulators take on an angular and rotary movement on the legs Torque that they give off when they relax. Torsion springs are made from round, oval or square spring steel wire – normally cylindrical with a constant pitch and no spacing between the windings. Depending on the application, the Leg out, for example, straight tangentially, radially inside or outside, axially or axially parallel. Particularly important: you should only ever load torsion springs in the direction of the coil. Therefore, they are offered with identical left and right-hand winding.

Compression springs

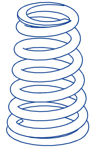

Compression springs , also called coil springs, are mechanical energy storage devices that absorb forces when they are compressed and release them again when they are relaxed. They are made from round, oval or square spring steel wires – usually cylindrical and with a constant slope. The Spring steel wire is cold formed. This is done either by winding it around a mandrel (one-finger system) and, with fully automatic spring coiling machines, with the help of wire guide pins (two-finger or three-finger system). In contrast to conventional compression springs with a constant pitch, the winding distances can vary. This influences the spring characteristic. To prevent the compression springs from snagging, turns in the middle or at the spring ends are often wound in a block.

Compression springs , also called coil springs, are mechanical energy storage devices that absorb forces when they are compressed and release them again when they are relaxed. They are made from round, oval or square spring steel wires – usually cylindrical and with a constant slope. The Spring steel wire is cold formed. This is done either by winding it around a mandrel (one-finger system) and, with fully automatic spring coiling machines, with the help of wire guide pins (two-finger or three-finger system). In contrast to conventional compression springs with a constant pitch, the winding distances can vary. This influences the spring characteristic. To prevent the compression springs from snagging, turns in the middle or at the spring ends are often wound in a block.

Kegelfedern

With the conical spring respectively conical compression spring the diameter of the design changes towards one end. That means it gets bigger or smaller. Conical springs are mainly used when the installation space is limited in the axial direction. With conical compression springs, the coils can fall into one another. This means that the block height is roughly twice the wire thickness and is therefore much smaller than for cylindrical compression springs . The springs can be with linear and progressive spring constant to construct. Normally the spring rate is or Spring constant progressive. That means that the Spring force increases with increasing load.

With the conical spring respectively conical compression spring the diameter of the design changes towards one end. That means it gets bigger or smaller. Conical springs are mainly used when the installation space is limited in the axial direction. With conical compression springs, the coils can fall into one another. This means that the block height is roughly twice the wire thickness and is therefore much smaller than for cylindrical compression springs . The springs can be with linear and progressive spring constant to construct. Normally the spring rate is or Spring constant progressive. That means that the Spring force increases with increasing load.

Barrel springs

The barrel spring is also called double-conical compression spring designated. Both ends of the spring have a smaller coil diameter than the center. Barrel springs usually have a linear and progressive characteristic. In addition, they impress with their small footprint and short overall length. A special form of the double-conical compression spring is the Mini block spring . It has an adapted coil diameter. As soon as the mini block spring is compressed to a short length, most of the coils fit into one another – without touching. This type of spring is often used in the axle suspension of a car. Depending on the requirements for a linear spring rate with fluctuating coils or for a progressive, increasing rate Spring rate , with constant turns.

The barrel spring is also called double-conical compression spring designated. Both ends of the spring have a smaller coil diameter than the center. Barrel springs usually have a linear and progressive characteristic. In addition, they impress with their small footprint and short overall length. A special form of the double-conical compression spring is the Mini block spring . It has an adapted coil diameter. As soon as the mini block spring is compressed to a short length, most of the coils fit into one another – without touching. This type of spring is often used in the axle suspension of a car. Depending on the requirements for a linear spring rate with fluctuating coils or for a progressive, increasing rate Spring rate , with constant turns.

Tension springs

Tension springs or coil springs are made from round or oval spring steel wires. These can be brought into the desired shape in the cold forming process – by winding them around a mandrel or with fully automatic spring coiling machines with the help of several wire guide pins. Are manufactured in addition to cylindrical Designs conical or barrel-shaped tension springs with a linear characteristic. With such conically tapered spring ends, in addition to a progressive spring characteristic, a longer service life of the springs is achieved. Depending on the application, the user can different eyelet shapes use. In addition to the classic eyelet shapes, such as the 1/1 German eyelet or hook eye, the range also includes resistant spring ends. These include rolled-up threaded bolts or screwed-in threaded plugs.

Tension springs or coil springs are made from round or oval spring steel wires. These can be brought into the desired shape in the cold forming process – by winding them around a mandrel or with fully automatic spring coiling machines with the help of several wire guide pins. Are manufactured in addition to cylindrical Designs conical or barrel-shaped tension springs with a linear characteristic. With such conically tapered spring ends, in addition to a progressive spring characteristic, a longer service life of the springs is achieved. Depending on the application, the user can different eyelet shapes use. In addition to the classic eyelet shapes, such as the 1/1 German eyelet or hook eye, the range also includes resistant spring ends. These include rolled-up threaded bolts or screwed-in threaded plugs.

Snap rings

Snap rings secure form-fitting components such as wheels, sealing elements and bearings in mechanical engineering Axles, shafts or within bores against axial displacement. The designation snap ring is derived from the earlier production method. At that time it was cut from pipes and then ripped open. Today snap rings are made of spring steel wire with a constant cross-section. They are bent into a ring on an automatic winding machine. The diameter can be a few millimeters to a few meters. Snap rings are available in two basic designs: for waves and for drilling .

Snap rings secure form-fitting components such as wheels, sealing elements and bearings in mechanical engineering Axles, shafts or within bores against axial displacement. The designation snap ring is derived from the earlier production method. At that time it was cut from pipes and then ripped open. Today snap rings are made of spring steel wire with a constant cross-section. They are bent into a ring on an automatic winding machine. The diameter can be a few millimeters to a few meters. Snap rings are available in two basic designs: for waves and for drilling .

Torsion springs: torsion bar springs

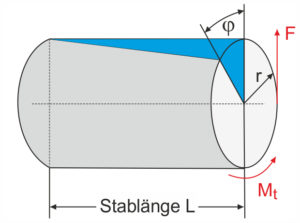

The Torsion bar belongs to the torsion springs. The term torsion spring is derived from the verb to twist, which means to twist or twist. Torsion bars are used, for example, as torsion pendulums in mechanical watches, as torsion bands in moving-coil measuring instruments, as a stabilizer for the suspension of vehicles and as a counterforce in sectional garage doors. The torsion bar spring has an elongated, rod-shaped structure and performs a rotary movement during its use. If the rod is twisted around its own longitudinal axis, this creates shear stress. This stress increases with the cross-sectional radius and is proportional to the torsional moment. The distribution of the shear stress is rotationally symmetrical in the bar cross-section. The twist angle is also proportional to the torsional moment and increases linearly with the rod length.

The Torsion bar belongs to the torsion springs. The term torsion spring is derived from the verb to twist, which means to twist or twist. Torsion bars are used, for example, as torsion pendulums in mechanical watches, as torsion bands in moving-coil measuring instruments, as a stabilizer for the suspension of vehicles and as a counterforce in sectional garage doors. The torsion bar spring has an elongated, rod-shaped structure and performs a rotary movement during its use. If the rod is twisted around its own longitudinal axis, this creates shear stress. This stress increases with the cross-sectional radius and is proportional to the torsional moment. The distribution of the shear stress is rotationally symmetrical in the bar cross-section. The twist angle is also proportional to the torsional moment and increases linearly with the rod length.

Individual spring application

Do you need a technical spring for your special application? Then simply send us the desired spring data – regardless of the type of spring – in the form of dimensional data, sketches, drawings or CAD data using the following Spring inquiry button or via email info@gutekunst-formfedern.de to. Our experts will be happy to make you an individual offer for the right technical spring.

Further information can also be found here: