The use of metal springs is diverse. Depending on the basic function (force distribution, movement, installation), there is a preferred spring selection. Whether metal springs made of flat material or wire material, read here what is important when developing a new metal spring.

The special property of technical springs is your reversible Change in shape when loaded . This is possible through the special shape and the used Spring material . Technical springs are used in almost all industries, such as mechanical engineering, Electrical engineering , Medical technology , Food industry , Aerospace, jewelry industry, etc. and perform numerous tasks. Technical springs, like Form springs , Flat springs , Flat springs , Contact springs , Compression springs , Tension springs and Coil springs , are often used as storage elements, measuring elements, vibration elements, rest elements and bearing elements.

Table of Contents

Spring technology

The basic function of all metal springs is based on their ability to store potential energy and convert it into kinetic energy in a controlled manner. For which force states technical springs are often used and which tasks they fulfill, here are a few examples:

-

Restoring force

The spring force is used as a counterforce to return the moving mass to its previous position of rest. This restoring force is the most common application of technical springs and is provided equally frequently by shaped springs, flat springs, compression springs, extension springs and torsion springs.

-

Adhesive force

In friction-locked connections, lock washers and spring washers provide compressive and adhesive forces that counteract unintentional loosening of screws and nuts, for example.

-

Balancing force

Technical springs are often used to compensate for changes in the shape, dimensions or position of other components, e.g. in the event of thermal expansion, or to maintain the electrical connection. Depending on the task, shaped springs, flat springs, contact springs, compression springs and torsion springs are equally suitable for this purpose.

-

Weight force

Used to distribute the load evenly between bodies. The best example of a spring core mattress that allows this weight force with special conical compression springs provides.

-

Driving force

The pre-tensioning of a metal spring stores energy, which is then released when the tension is released and drives moving devices. With Coil springs For example, mechanical watches are driven or flexible dog leashes are rolled up.

-

Vibration and damping force

When kinetic energy is absorbed by incoming forces or impacts, the metal spring deforms. When the mass swings out, this kinetic energy is then converted back into potential energy. For example, Leaf springs for safe loading from forces and impacts.

Spring development

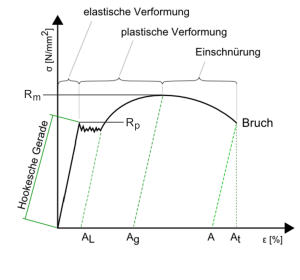

When developing a technical spring it is the goal for the given application one matching spring to find the one that fits perfectly, taking into account all the circumstances. The function, shape and dimensions must be selected so that the technical spring provides the required Spring work Fulfills. Various factors play an important role in spring development – such as which one Stress and deformation ( Hooke’s law ) the technical spring must fulfill, which spring movement is desired, how large the available installation space is and which connecting components are present. In addition, there are properties and special features from the overall construction and the operating conditions. So are often among other things Corrosion resistance , electric conductivity or to consider a production that is as economical as possible. In general, the following requirements for spring development apply to technical springs:

-

Task and function

What is the technical spring used for (medical technology, food, electrical engineering, etc.) and what functions – such as force state, force development(spring characteristic curve) and any additional functions (electrically conductive, non-magnetic, insulating, acid-resistant, medically pure, etc.) – are required?

-

Installation situation and installation space

How is the force introduced (compression, tensile, torsional or bending stress) and what installation space is available for this?

-

Feather type and shape

Which Spring type is suitable for the task and with which spring shape can this be implemented in the existing installation space?

-

Required forces and spring travel

What spring forces are required for certain spring travels or lengths?

-

Operating temperature and environment

In which Operating temperature and in which environment (Air, salt water, engine oil etc.) is the technical spring used?

-

Type of load and service life

Which Load type There is a static constant load or dynamic load with variable loads and stroke stresses. For what total service life should the technical spring be made?

Development and manufacture of technical springs

If you have any further questions about metal springs, or if you need an expert design with a non-binding quotation for your spring application. Then simply send us a drawing or CAD data of the metal spring you require using the following inquiry form or the Formfedern store. Or you can contact the Gutekunst technicians directly by telephone on (+49) 07445 85160 or by e-mail to: info@gutekunst-formfedern.de.

Gutekunst Formfedern develops and manufactures technical springs such as form springs, flat springs, contact springs and spiral springs as well as Gutekunst Federn compression springs, tension springs and torsion springs as samples, prototypes, in small quantities and large series.

Benefit from the new Formfedern store

The new form spring store from Gutekunst Formfedern offers several advantages in the procurement of form springs, flat springs, laser parts and sheet metal parts. Thanks to its simple operation, transparent online price calculation and fast digital processing, it is a real support for designers, technicians and purchasers. At last, it is possible to configure, calculate prices, make inquiries and place orders for tailor-made formed metal parts in an uncomplicated and time-saving manner – around the clock and with maximum transparency.

Try it out for yourself at https://shop.formfedern.com

Formfedern-Shop

For more information, see: