Table of Contents

What are coil springs?

Spiral springs are made of spiral springs Spring band steel or flat material and are produced individually according to customer requirements. They are wound in a plane following the Archimedean spiral. The constant distance between the coils prevents the individual coils from touching and ensures that the spring functions with little friction. Spiral springs are used in the component in such a way that one end is connected to a shaft and the other to the housing. Due to their spiral shape, they are ideally suited as compensating springs for smaller angles of rotation: The stored force serves as compensation or as a restoring torque. The Spring characteristic increases almost in a straight line.

Where are coil springs used?

Spiral springs can be used in drives as measured value sensors or vibration transmitters. A large number of other applications are possible – for example as working memory for clockworks, resetting the pointers of measuring instruments or as links in elastic couplings. They play an important role in the automotive industry and are installed in seat belts, window regulators and locks, among other things. They are also used in plant and mechanical engineering as well as in mechanical and precision engineering devices.

Coil springs load options

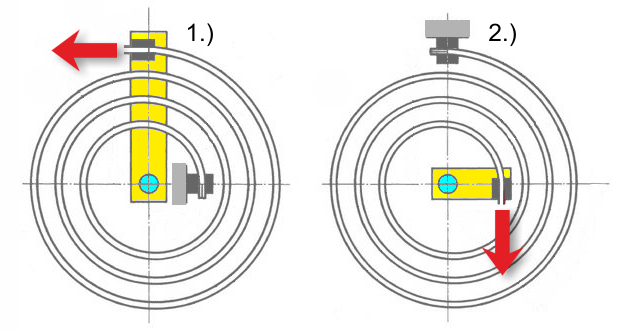

With a spiral spring, either the outer (1) or the inner end (2) is loaded.

1) = external actuation

2) = internal actuation spiral springs

Where can you order coil springs?

The special thing about spiral springs: They are not available as a standard product from the catalog. Gutekunst Formfedern GmbH specializes in the production and sale of spiral springs and manufactures them according to customer specifications from different Spring band steels . The spiral springs are produced on radial bending machines. Gutekunst Formfedern offers spiral springs in steel strip thicknesses of 0.4 to 3.0 millimeters and in a bandwidth of 5.0 to 40 millimeters.

Additional finishing through surface treatment

Gutekunst Formfedern also includes one final surface treatment to the different Spring band steels to be refined afterwards. The procedures include, for example Thick film passivation , Bright galvanizing such as Powder or Teflon coating . If desired, the spiral springs can also be treated so that they are then electrically conductive, medically pure or particularly resistant. This means they can be used in a variety of ways.

It’s that easy to order spiral springs

Would you like to order spiral springs? Simply send your CAD data, a drawing or sketch, information about the installation situation and the operational environment as well as the desired function to info@gutekunst-formfedern.de or call (+49) 07445 85160. Based on this data, we will be happy to prepare an individual offer for you.

For more information: