Shaped springs and flat springs are manufactured in any desired shape and function from spring steel sheet and spring steel strip and belong to the leaf spring product group. They are diverse construction elements when it comes to absorbing and transmitting forces with relatively large deformations. Form springs store potential energy during mechanical work, which they can release again at a specific point in time. The applications of shaped springs are inexhaustible. They range from simple flat springs or flat springs up to complex ones, precisely adapted to the geometry of the surrounding components form springs . Shaped springs and flat springs are often used in mechanical engineering, vehicle construction, the food industry, medical technology, precision engineering and electrical engineering. Shape springs are often used as storage elements for force and path compensation, as measuring elements in force and torque sensors, as vibration and damping elements in suspension springs and as rest elements in contact springs and locking springs inserted.

Shaped springs and flat springs are manufactured in any desired shape and function from spring steel sheet and spring steel strip and belong to the leaf spring product group. They are diverse construction elements when it comes to absorbing and transmitting forces with relatively large deformations. Form springs store potential energy during mechanical work, which they can release again at a specific point in time. The applications of shaped springs are inexhaustible. They range from simple flat springs or flat springs up to complex ones, precisely adapted to the geometry of the surrounding components form springs . Shaped springs and flat springs are often used in mechanical engineering, vehicle construction, the food industry, medical technology, precision engineering and electrical engineering. Shape springs are often used as storage elements for force and path compensation, as measuring elements in force and torque sensors, as vibration and damping elements in suspension springs and as rest elements in contact springs and locking springs inserted.

Table of Contents

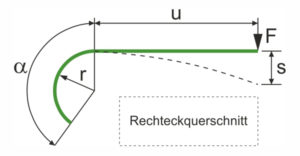

Design and calculation of form springs and flat springs

When designing an optimum shaped spring and flat spring, including determining the spring shape and dimensions, the spring fastening, the appropriate spring material and the manufacturing and testing options, many years of sound experience are required. Because the individual and complex shape means that it is standardized interpretation and calculation only to a limited extent by calculating bending radii and bending stresses possible. A shaped spring is designed iteratively with proof of strength and functionality. For the design, in addition to the complex finite element method, many years of practical experience are necessary. Therefore documented Gutekunst Formfedern in detail with each production, construction-related information for the following interpretations of shaped springs .

When designing an optimum shaped spring and flat spring, including determining the spring shape and dimensions, the spring fastening, the appropriate spring material and the manufacturing and testing options, many years of sound experience are required. Because the individual and complex shape means that it is standardized interpretation and calculation only to a limited extent by calculating bending radii and bending stresses possible. A shaped spring is designed iteratively with proof of strength and functionality. For the design, in addition to the complex finite element method, many years of practical experience are necessary. Therefore documented Gutekunst Formfedern in detail with each production, construction-related information for the following interpretations of shaped springs .

Form springs and flat springs in small quantities and large series

As an experienced manufacturer of shaped springs turns Gutekunst depending on requirements, shape and number of pieces, the pure one bending process or stamping and bending process as well as for small quantities and complex shapes laser cutting with the following reshaping by bending, folding, embossing and deep drawing. There are no limits to the design of shaped springs. Final surface treatments such as vibratory grinding, barrel finishing, phosphating, burnishing, galvanizing, painting etc. are also offered on request, as is the pressing in of threaded bolts, for example, or direct installation in the components provided. Besides the normal spring steel strips and spring steel sheets Stainless steels, non-ferrous metals and non-ferrous metals are offered in strip form or plate form for the production of shaped springs.

Gutekunst production dimensions of shaped springs and flat springs

Material thicknesses: 0.1 to 3.0 mm

Strip widths: 1.0 mm – 150 mm

Plate sizes: 1500 x 2500 mm

Manufacturing techniques: Lasering, punching, etching, bending, folding, embossing, soldering, nibbling, joining, pressing in, grinding, thread cutting, welding, assembly

Spring materials:

Spring steel (EN 10270-1), stainless steel (1.4310, 1.4571 and 1.4568), aluminum (Al, AlMg3 and S235JR), non-ferrous metals such as various copper alloys bronze (CuSn), brass (CuZn) and numerous other special alloys

Surface treatments : Zinc plating (Zn), copper plating (Cu), nickel plating (Ni), silver plating (Ag), gold plating (Au), vibratory finishing, barrel finishing, deburring, phosphating, burnishing, lacquering … other surface treatments on request

Gutekunst range of shaped springs and flat springs

Gutekunst Formfedern develops and manufactures form springs and flat springs according to customer requirements as samples, prototypes, in small quantities and large series. If you are interested, simply send us the data for the required form spring and flat spring, stating the quantity and the drawing or CAD data, using the following form spring inquiry form or by e-mail to info@gutekunst-formfedern.de. We will prepare a non-binding offer for you at short notice. You can also reach our technicians by telephone on (+49) 07445 85160.

Anfrage Formfedern & Flachfedern

For more information, see: