When forming shaped springs, flat shaped springs, spring clips, contact springs and leaf springs, the rolling direction of the spring steel sheet and spring strip steel is an important factor, among other things. This is because the stretching of the material during rolling results in a fibrous material structure whose fiber elongation always occurs in the direction of rolling.

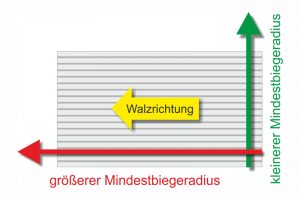

When forming shaped springs, flat shaped springs, spring clips, contact springs and leaf springs, the rolling direction of the spring steel sheet and spring strip steel is an important factor, among other things. This is because the stretching of the material during rolling results in a fibrous material structure whose fiber elongation always occurs in the direction of rolling.

If the spring steel sheet is now bent along this fibre elongation or rolling direction, a larger minimum bending radius must be selected due to the higher risk of breakage. However, if the spring steel sheet is bent transversely to the fibre elongation, the minimum bending radius can be made smaller. This improved property of the spring steel strip or spring steel sheet can improve the yield strength or yield point by up to 15% for shaped springs, flat springs and metal components bent at right angles to the rolling direction.

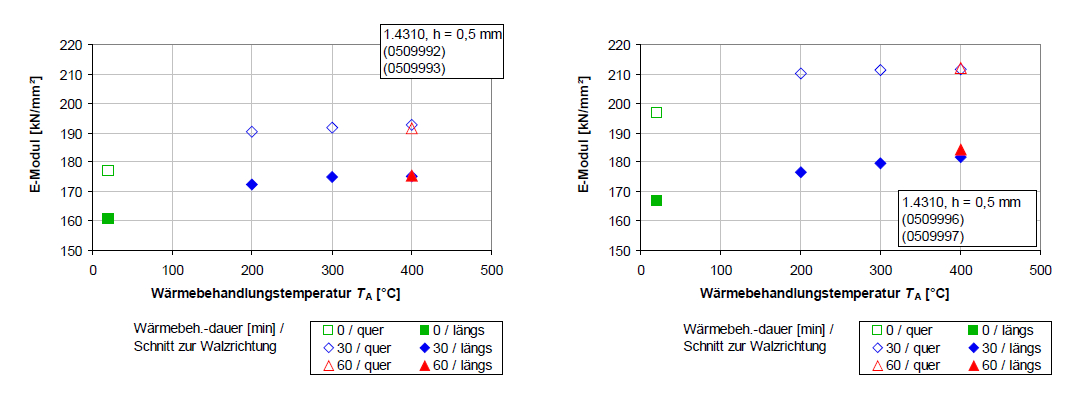

The improvement in yield strength , or yield point, for metal formed parts bent transversely to the rolling direction is, for example, between 4 and 10% for spring steel 1.4310 with low strength (left graph) and up to 15% for high strength (right graph). This significant difference in the mechanical characteristics must be taken into account when designing shaped springs that are bent longitudinally or transversely to the rolling direction.

The correct pressing force during forming

In addition to the rolling direction, the pressing force plays an important role in the forming of shaped springs, flat shaped springs and metal formed parts. In order to permanently transform the spring steel, the value of the yield strength (Rp) must be exceeded. If this is not the case, the metal returns to its original state. Only a load above the yield point (Rp), or yield strength (Rp0.2) causes plastic deformation. It is essential to ensure that the tensile strength of the spring material (Rm) is not exceeded, otherwise the material could be damaged.

Our technicians will be happy to determine which forming parameters are optimal for your shaped spring, flat shaped spring, contact spring, spring clip, leaf spring and spring washer. To do this, simply send us the required spring data with details of the number of pieces and the drawing or CAD data using our enquiry form for shaped springs.

Anfrage Formfedern & Blattfedern

Gutekunst Formfedern will be pleased to check the forming parameters and provide you with a non-binding offer at short notice. In addition to the enquiry form, you can also contact our technical department directly at info@gutekunst-formfedern.de and telephone (+49) 07445 85160.

You can find more interesting topics at: