Every material has a certain conductivity. So-called non-conductors, electrical insulating materials and insulators also conduct electricity, albeit in negligible amounts. It looks different with Metals out. Most metals are good conductors. Your conductivity depends on the availability and density of mobile charge carriers. To put it simply: the more freely movable charge carriers there are in a metal, the better it conducts the electrical current.

Use of conductive metals

We know two different uses for electricity: the transmission of energy and information. Both cases have one thing in common: You need electrical conductors with you specific shape and individual properties. Usually come for it Contact springs are used, which are available in an almost infinite number of variants and designs. They bridge and close contact points to enable the flow of electricity, for example with one Battery contact .

Gutekunst Formfedern GmbH specializes in the manufacture of such individual contact springs and manufactures them in any special shape and property. It does not matter whether it is a simple one Flat contact or an elaborately shaped one Contact spring acts – it is important that the element is optimally adapted to the requirements and that it rests firmly on the contact points.

Electrical conductivity of various metals

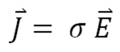

The physical size specification “electrical conductivity of metals” has the symbol sigma (σ) and is measured in Siemens per meter (S / m). Its reciprocal value, the specific resistance Ω (omega) is given in microohms per meter (m).

The formula for electric conductivity is defined as the constant of proportionality between the current density and the electric field strength

:

Electrical conductivity and specific resistance of selected metals at 20 to 25 ° C

| Attention: The degree of purity of the metals can influence the electrical conductivity. | ||

| material | Conductivity σ in S / m | Resistance Ω in m |

| silver | 61 · 10 6th | 0.0160 x 10 -6 |

| copper | 58 · 10 6th | 0.0175 x 10 -6 |

| gold | 45 · 10 6th | 0.0220 x 10 -6 |

| aluminum | 37 · 10 6th | 0.0270 x 10 -6 |

| tungsten | 19 · 10 6th | 0.0550 x 10 -6 |

| iron | 10 · 10 6th | 0.1000 x 10 -6 |

| Edelstahl | 1.4 x 10 6th | 1.0000 10 -6 |

Silver, copper and gold share the winners’ podium. aluminum reaches around 65 percent of the conductivity of copper, so it is a good electrical conductor, but only comes in fourth. The bottom light of the table with the lowest conductance is the stainless steel .

Contact springs made of copper beryllium (CuBe)

Due to their high price, silver and gold are rarely used as raw materials for contact springs. Often times these are made out instead Copper beryllium (CuBe) manufactured. This is characterized by its high strength and excellent spring properties. The material is also self-cleaning and resistant to air, ozone, solvents and UV light. It can even withstand nuclear radiation. In addition is CuBe thermally and electrically conductive.

Contact springs made from other metals

In addition to copper beryllium (CuBe) can Contact springs Depending on the application and properties, there are also numerous others Metals are manufactured. Spring steel (EN 10270-1), stainless steel (1.4310, 1.4571 and 1.4568), aluminum (Al and AlMg3), non-ferrous metal alloys such as bronze (CuSn) or brass (CuZn) as well as numerous special alloys are possible.

To improve conductivity, Gutekunst can use the surfaces Coat the manufactured components with zinc (Zn), copper (Cu), nickel (Ni), silver (Ag) or gold (Au) or passivate the springs. This improves the contact and the components can be processed more easily. The different coatings give them different properties. With gold, for example, resistance to most acids and very good surface protection can be achieved. If the user needs a component that can be welded or soldered well and reliably, coatings with zinc or gold are the right choice.

Individual development and manufacturing

You need the right one Contact spring or one special battery contact for your application? Then send your CAD data, a drawing or a sketch, as well as information on the installation situation, operational environment and the desired function via the following Inquiry button contact springs or at info@gutekunst-formfedern.de . You can also reach our technical department by phone at (+49) 07445 8516-0.

For more information: