stainless steel is a frequently used material with many good properties. It is corrosion-resistant and durable, can be used in a wide temperature range, is easy to clean and chemically and microbiologically resistant. Thus, stainless steel can not only be used well in the corrosive environment but also in areas with high hygienic requirements, such as the Medical technology and the Food industry .

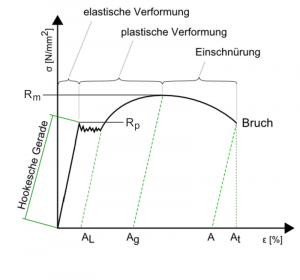

For production of Form springs , Flat springs , Contact springs and Leaf springs must they Stainless steel sheets and strips have a very good plastic deformation capacity. One value for the deformability of stainless steel is the tensile strength . This tensile strength value describes the plastic deformation limit im Stress-strain diagram of the material.

Table of Contents

Calculation of tensile strength

The tensile strength becomes during a tensile test from the maximum tensile force achieved

based on the cross-section

calculated from a standardized tensile test.

Tensile strength of stainless steel sheets and strips

The following are the tensile strength values of the most common types of stainless steel in spring production. The values for the tensile strength refer to the condition of the stainless steel sheets and strips after Heat treatment .

| Spring steel type | X10CrNi18-8 |

| Material number | 1.4310 |

| description | X10CrNi18-8 / 1.4310 is an austenitic chrome-nickel spring steel with good formability. Due to its special mechanical properties, this material 1.4310 is the classic among the stainless spring steels and is often used in the production of corrosion resistant Spring components used. Since with this stainless spring steel sheet and spring band steel 1.4310 by the Cold deformation a slight magnetizability arises, this material is not suitable for completely non-magnetic springs. |

| Tensile strenght ( |

1500 to 1700 N / mm² |

| modulus of elasticity | 200 kN / mm² |

| Max. Operating temperature | -200 to 250 ° C |

| Spring steel type | X7CrNiAl17-7 |

| Material number | 1.4568 |

| description | X7CrNiAl17-7 / 1.4568 is a stainless, precipitation-hardenable chrome-nickel-aluminum alloy spring steel. The spring steel sheet or the spring band steel 1.4568 has very good long-term properties and very good corrosion resistance with minimal distortion the heat treatment . In the hardened state, spring steel 1.4568 has excellent mechanical properties up to 350 ° C. |

| Tensile strenght ( |

900 to 1100 N / mm² |

| modulus of elasticity | 200 kN / mm² |

| Max. Operating temperature | -200 to 350 ° C |

| Spring steel type | X5CrNiMo17-12-2 |

| Material number | 1.4401 |

| description | X5CrNiMo17-12-2 / 1.4401 is an austenitic chromium-nickel-molybdenum steel with very good corrosion resistance to non-oxidizing acids and media containing chlorine and is suitable for applications in the food industry and partly in the Medical technology . Spring steel sheets and spring steel strips made of 1.4401 have a lower strength than 1.4310 and 1.4568. On the other hand, the corrosion resistance is significantly higher and the magnetizability is lower. |

| Tensile strenght ( |

1100 to 1400 N / mm² |

| modulus of elasticity | 200 kN / mm² |

| Max. Operating temperature | -200 to 300 ° C |

See more information about the Calculation of shaped springs , Flat springs , Contact springs and Leaf springs . If necessary to technical springs For your special application, simply contact our technical department by email info@gutekunst-formfedern.de . You are welcome to contact us at the following Inquiry form You can also simply send your spring data with details of the number of pieces and the drawing, sketch or CAD data. We will prepare a non-binding offer for you at short notice.

For more information: