The offer of Metal springs is as extensive as his Possible applications . In order to procure the optimal metal spring for the respective application, you need a partner who is very familiar with all manufacturing processes. the Gutekunst Formfedern

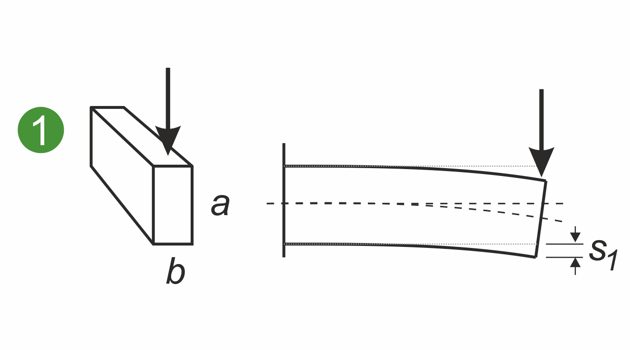

Shaped springs, stamped and bent parts and laser parts according to customer requirements