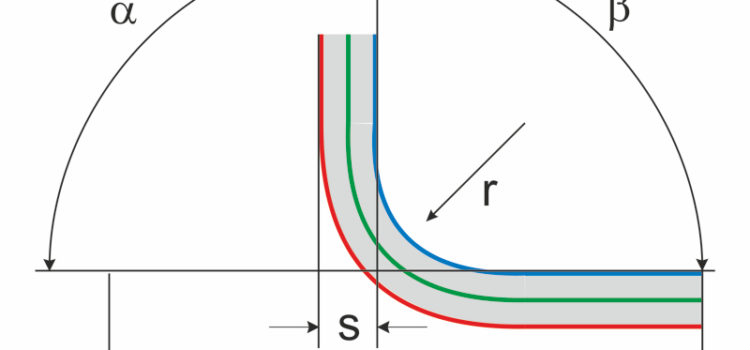

Drawing parts are industrial metal parts that are manufactured according to customer requirements – as prototypes, in small quantities or in large series. The range of drawing parts, which are manufactured according to CAD data, drawings and samples, extends

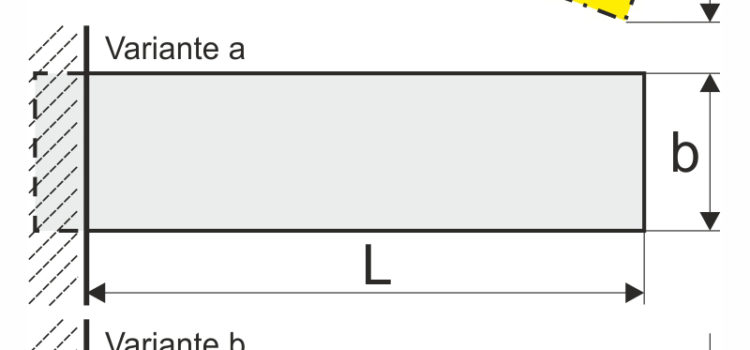

Customized drawing parts