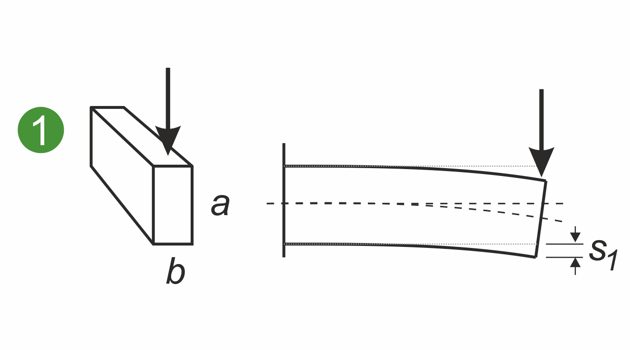

Under the umbrella term Leaf springs become different Types of feathers summarized, which can be used in countless applications. They range from simple spiral springs and flat springs to complex form springs and parabolic springs that adapt precisely to the

Leaf springs selection