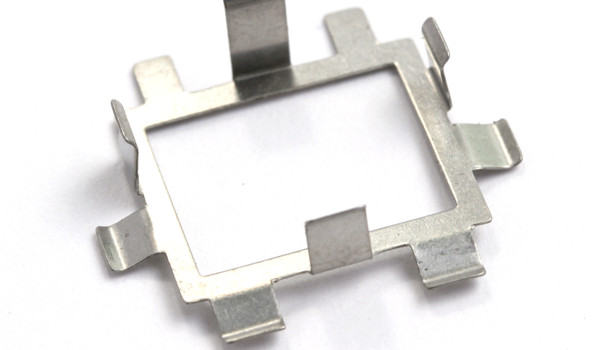

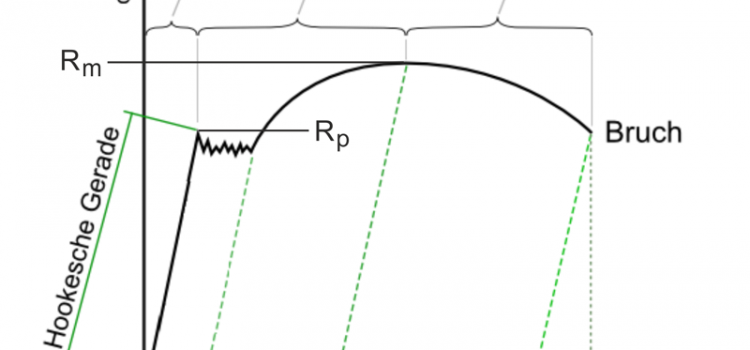

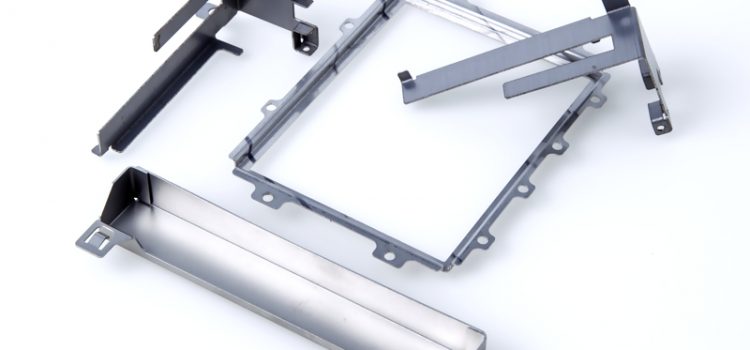

The use of metal springs is diverse. Depending on the basic function (force distribution, movement, installation), there is a preferred spring selection. Whether metal springs made of flat material or wire material, read here what is important when developing a

Optimal use of metal springs