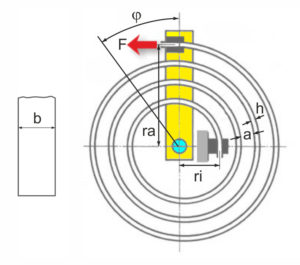

Coil springs will be off Spring band steel produced. Spiral springs are coiled in a plane of the Archimedean spiral. The constant distance between the coils (a) prevents the individual coils from touching and ensures that the spring functions with little friction. Spiral springs are used in the component in such a way that one end is connected to a shaft and the other to the housing. Due to their spiral shape, they are ideally suited as compensating springs for smaller angles of rotation of up to 360 °. The stored force serves as a compensation or as a restoring torque. The spring characteristic of a spiral spring increases in a straight line.

Table of Contents

Formulas for calculating a spiral spring with coil spacing

- a = winding spacing

- b = bandwidth

- φ = angle of rotation

- E = modulus of elasticity

- F = spring force

- h = tape thickness / material thickness

- lw = effective belt length

- n = number of turns

- I = moment of inertia

- ra = outer radius of the spring body

- ri = inner radius of the spring body

Torque

\Large M = \frac{E\cdot I \cdot \varphi }{57.3 \cdot lw} \Large \frac{E \cdot b \cdot h^{{3}} \cdot \varphi}{690 \cdot lw}Bending stress

\Large \sigma = \frac{6 \cdot M}{b \cdot h^{{2}}}Spring torque rate

\Large R_{MR} = \frac{M}{\varphi} = \frac{E \cdot b \cdot h^{{3}}}{690 \cdot lw}Torsional moment

\Large M_{{t}} = F \cdot raMaximum angle of rotation

\Large \varphi_{{max}} = \frac{180}{\pi} \frac{2 \cdot lw\sigma}{h \cdot E} \Large \frac{180}{\pi} \frac{M \cdot lw}{E \cdot I}Effective tape length

\Large lw = \pi \cdot n \left ( ra + ri\right )Outer radius

\Large ra = ri + n \left ( h + a\right )Spring work

\Large W = \frac{1}{2} M \cdot \varphi

Differentiation between coil springs and mainsprings?

Power springs are spiral springs without a coil spacing. Although they also have space between the turns when they are not tensioned, they are not made with a special pitch between the turns. Power springs are mostly used for large angles of rotation of up to 20 revolutions and more. Depending on the load profile, they generate more or less friction and are usually built into a housing. The spring characteristic of the mainspring is irregular.

If you need an individual spring and mainspring, simply send us to info@gutekunst-formfedern.de or about the following Spring inquiry button the required spring data with a sketch, drawing or CAD data for your application.

Further information