The stress-strain diagram can be used to determine the static load capacity of spring steel. The stress-strain diagram shows the elongation behavior of the spring steel during the tensile test until it breaks. For the designer, the stress-strain diagram is an important design specification, as he can read off from this diagram how much force the spring steel sheet or spring steel strip can absorb during forming for the production of shaped springs, spring clips, spring clips, contact springs and spring washers until it is permanently deformed.

Table of Contents

The phases of the stress-strain diagram for spring steel

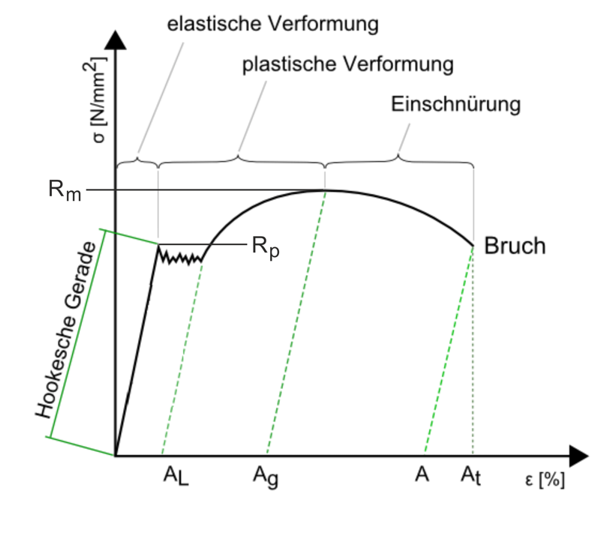

With the four phases in the stress-strain diagram, the elastic deformation limit (yield strength “Rp”), the plastic deformation limit (tensile strength “Rm”), the necking range and the breaking limit can be read.

In the phase of elastic deformation, the spring steel is stretched proportionally (Hooke’s straight line) to the applied stress. This strain is also called linear-elastic or proportional deformation. The percentage strain is displayed in the horizontal axis and the corresponding stress in the vertical axis. This deformation behaviour of materials was already described in 1768 by the English scholar Robert Hooke in Hooke’s Law. When the maximum elastic deformation is reached at which the spring steel returns to its initial position without deformation, this is called the yield strength (Rp). The yield strength is a yielding limit. Beyond this yield point, deformation still takes place in the subsequent phases, but here the strain is greater than the increasing stress, resulting in plastic deformation and necking down to failure.

The 0.2 % proof stress

The 0.2 % proof stress

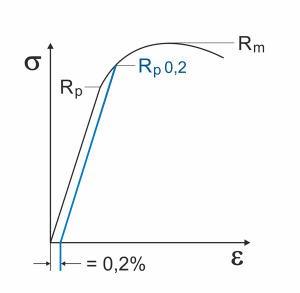

There are spring materials for which the yield strength cannot be clearly determined. This applies above all to stainless spring steels. Alternatively, the yield strengthRp0.2 is specified here. For this purpose, a parallel to Hooke’s straight line is drawn at a distance of 0.2%. This stress at the intersection corresponds to the yield strength Rp0.2 as a substitute for the yield point.

Material properties

The tensile strength (Rm) is the most commonly used material parameter. This value is the basis for every spring calculation and describes the maximum load capacity of a spring steel. However, it should be noted that the spring steel deforms plastically even before the tensile strength is reached! The yield strength (Rp) and the yield stress (Rp0.2) are normally listed on the manufacturer’s data sheets or can be requested from the material manufacturer.

You need more information about the stress-strain diagram and the material properties? No problem, you can reach the technical department of Gutekunst Formfedern GmbH by phone at (+49) 07445 85160 or info@gutekunst-formfedern.de.

If you are also interested in individual form springs, spring clips, spring clamps, contact springs and spring washers, simply use our inquiry form. We will prepare a non-binding offer for you at short notice.

Spring request

For more information: