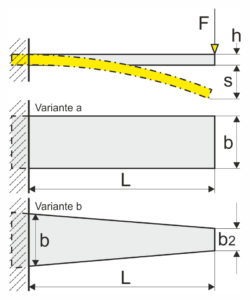

With the leaf spring or flat spring clamped on one side, the maximum bending stress, spring force, spring deflection (deflection), spring leaf thickness and spring rate can be calculated as follows. The bending stress increases linearly with the leaf spring or flat spring clamped on one side with an increase in force at the point of force application. With the rectangular leaf spring (variant a) the highest bending stress only at the clamping point. Thus, the rectangular leaf spring only develops its full benefit at the clamping point. In contrast, the trapezoidal leaf spring (variant b) a more uniform bending stress in cross section. As a result, the spring work of the trapezoidal leaf spring is up to three times better than that of the rectangular leaf spring, depending on the size of the trapezoid. A triangular shape would be ideal, but due to the design it can rarely be used.

With the leaf spring or flat spring clamped on one side, the maximum bending stress, spring force, spring deflection (deflection), spring leaf thickness and spring rate can be calculated as follows. The bending stress increases linearly with the leaf spring or flat spring clamped on one side with an increase in force at the point of force application. With the rectangular leaf spring (variant a) the highest bending stress only at the clamping point. Thus, the rectangular leaf spring only develops its full benefit at the clamping point. In contrast, the trapezoidal leaf spring (variant b) a more uniform bending stress in cross section. As a result, the spring work of the trapezoidal leaf spring is up to three times better than that of the rectangular leaf spring, depending on the size of the trapezoid. A triangular shape would be ideal, but due to the design it can rarely be used.

Table of Contents

Formulas:

Maximum bending stress

\Large \sigma_{{b}} = \frac{M}{W} = \frac{6 \cdot F \cdot L}{b \cdot h^{2}} \leq \sigma_{{b zul}}

Maximum spring force

\Large F_{{max}} = \frac{b\cdot h^{2} \cdot \sigma_{{b zul}}}{6 \cdot L}

Spring travel (deflection)

\Large s = q_{1} \cdot \frac{L^{3}}{b \cdot h^{3}} \cdot \frac{F}{E}

\Large q_{1} for rectangular leaf spring (variant a) \Large q_{1} = 4

\Large q_{1} for trapezoidal leaf spring (variant b) \Large q_{{1}} \approx 4 \cdot \left [ 3/ \left ( 2+b2/b \right )\right ]

Maximum spring deflection (deflection)

\Large s \leq q_{{2}} \cdot \frac{L^{2}}{h} \cdot \frac{\sigma_{{b zul}}}{E}

Maximum spring leaf thickness

\Large h \leq q_{{2}} \cdot \frac{L^{2}}{s} \cdot \frac{\sigma_{{b zul}}}{E}

\Large q_{2} for rectangular leaf spring (variant a) \Large q_{2} = 2/3

\Large q_{2} for trapezoidal leaf spring (variant b) \Large q_{{2}} \approx \left ( 2/3 \right ) \cdot \left [ 3/ \left ( 2+b2/b \right )\right ]

Spring rate

\Large C = \frac{F}{s} = \frac{Ebh^{3}}{4L^{3}}

b = width of leaf spring (mm)

b2 = smaller width of trapezoidal leaf spring (mm)

E = modulus of elasticity

F = spring force (N)

h = material thickness spring plate / spring leaf (mm)

L = length of leaf spring (mm)

s = spring deflection (mm)

Gutekunst Formfedern develops and manufactures individual products Leaf springs , Flat springs and Form springs as samples, prototypes, in Small quantities and large series. If you are interested, simply send us the data for the required form spring, stating the quantity and the drawing or CAD data, using the following inquiry button or by e-mail to info@gutekunst-formfedern.de. We will prepare a non-binding offer for you at short notice.

For more information, see: